The DFW Hospital Council posts guest blogs by Associate Members. The following was provided by OSPECS Consulting, LLC.

There is an unsung hero in the fight against COVID-19: the sterile processing department of your local hospital. The Sterile Processing Department (SPD) and its technicians are charged with cleaning, preparing and sterilizing any reusable medical device used on patients.

Often overlooked—it is frequently located in the basement of your hospital—this department is as crucial as doctors treating patients. Without careful decontamination, disinfection and sterilization of life-saving equipment, doctors might not have the tools they need to save lives and hospitals might spend hundreds of thousands of dollars to buy new what is otherwise reusable equipment.

After surgeries or procedures, a sterile processing technician must transport contaminated (read: used) instruments from the operating room to the decontamination area and remove all bioburden that remains on the tools. This is more than simple soap and water. Techs must decontaminate delicate and expensive equipment, disassemble complex instruments, use special brushes to reach small spaces, deploy powerful disinfectants and detergents, and adhere to manufacturers’ instructions for correct processing.

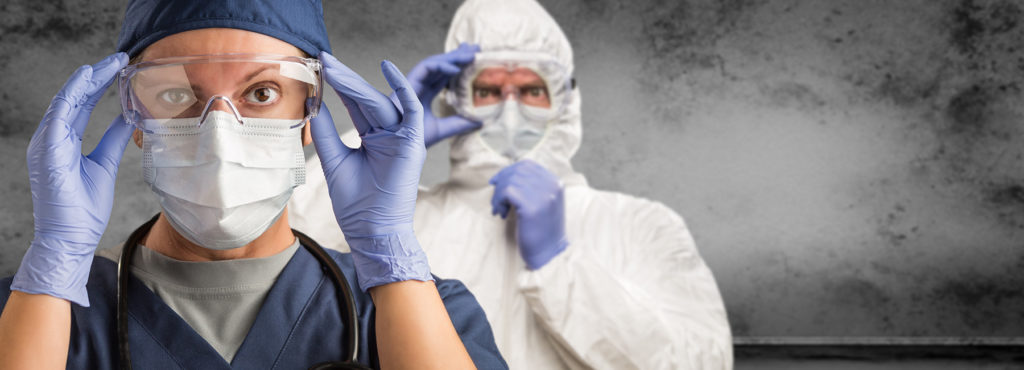

Most important, a sterile processing technician must keep themselves safe. The personal protective equipment, or PPE, required to process contaminated equipment is no different than what might be used in the OR. These include heavy duty gloves, impervious gowns, surgical mask and a face shield to protect against contaminants found in the surgical devices.

Never before has the sterile processing department been so consequential while being so under siege. COVID-19’s high contagion rate requires that we reexamine what is already-strict processing protocol to protect the health of techs who may have just a few days of on-the-job training. After working with a preceptor, they are soon responsible for protecting the health of patients and doctors who will be exposed to the sterilized and decontaminated tools.

Here are a few crucial steps we can take to protect our techs, doctors and patients from the spread of COVID-19:

• Continue to follow universal precautions. Everything that arrives in the decontamination area should be considered contaminated.

• Follow recommended standards for reprocessing surgical instruments.

▶ AAMI ST79 Comprehensive guide to steam sterilization and sterility assurance in health care facilities.

▶ AAMI TIR68 Low and intermediate level disinfection for medical devices and sterile processing environmental surfaces.

• Follow the medical device, detergent and disinfectants manufacturers’ instructions for use.

▶ Know what it takes for a medical device to be considered decontaminated. Learn how it is disassembled for cleaning, and know which parts need to be cleaned.

▶ Apply the correct, validated detergents and disinfectants for each device.

▶ Rinse thoroughly before applying the disinfectant solution.

▶ Adhere to the proper contact time for each solution. This is the amount of time the solution must remain wet on the device surface.

• Follow the standards for handling, collection and transportation and containment of contaminated medical devices.

▶ AAMI ST79: Section 6: provides guidelines for handling and transport of contaminated items.

▶ OSHA standards for exposure of blood-borne pathogens.

▶ Use leak-proof bins in closed carts for transport. Ensure the cart is labeled as a biohazard.

▶ Do not leave cart unattended during transport.

▶ Disinfect bins and carts after each use.

• Do not perform any tasks in the decontamination area without the appropriate PPE.

▶ Follow the proper sequence for putting on (donning) and removing (doffing) PPE. Download the CDC poster at https://www.cdc.gov/hai/pdfs/ppe/ppe-sequence.pdf with an easy-to-follow photo sequence.

▶ Wear appropriate PPE. Long-cuff gloves prevent the water from touching skin, and leak-proof gowns prevent the technician from getting wet during the cleaning procedures. Face shields will protect from splashes.

▶ Immediately change the PPE if it gets wet.

• When hand-washing devices, follow steps listed in a device’s IFU.

▶ Brush devices under running water to prevent aerosolization.

▶ Clean the sink after each tray.

▶ Use disposable sponges or wash cloths and dispose them after each use.

• Disinfect all contact surfaces in the decontamination area.

▶ Clean with disinfectant solution all countertops and carts; washer decontaminator panels; ultrasonic cleaner; doser buttons and panels; water facets; magnifying glasses; cabinet handles; and doorknobs.

▶ Follow the brushes’ IFUs. Some may be disinfected, other may be thrown out.

• Practice frequent, effective hand washing. Scrub for :20 seconds with soap and water or a hospital-approved hand sanitizing solution.

Visit our webpage at www.ospecsconsulting.com to learn more about how OSPECS Consulting can help transform your readiness processes. Staying prepared and educated can save lives, especially during these unprecedented times.